Browse our Catalogue

Do you need help choosing the right product for your application? Please email the details for your process to: sales@lev-co.com.Click on section title for more information. Don't forget to scroll down for more products and info!

An extraction arm is a capture or receiving device designed to capture aerosols at the emission point before the contaminants have a chance to reach the workers' breathing space. Typically, it is the first and most crucial part of an LEV or Local Exhaust and Ventilation system. NB: Local exhaust ventilation can also be referred to as process ventilation or Industrial Ventilation, or Local Control ventilation.

Available in several different designs:

- Internally Supported

- Externally Supported

- Telescopic

- Mild or Stainless Steel Construction

- Lengths: Up to 45'

- 2.5" to 8" Ø Available

Typically the Extraction Arms are connected to a fixed extraction fan, Filter system or dust collector via direct mounting or a "Header Type" duct system.

For more info, relate to the links below:

Welding Productivity

Solidswiki

- Aerospace - Aluminum Welding

- Aerospace - Steel Welding

- Art's - Jewelry Manufacturing

- Art's - Lithography

- Art's - Screen Printing

- Art's - Stained Glass

- Auto body repair - Aluminum Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Plastic Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Rubber Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Dental Offices - Operating Room

- Dental Offices - Procedure Room

- Educational - Auto Shop

- Educational - Chemistry Laboratories

- Educational - Machine Shop

- Educational - Welding Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Canning

- Food & Beverage - Food Packaging Plant

- Food & Beverage - Fruit Production

- Forensics - Forensic Laboratories

- Machine Shop - Aluminum Welding

- Machine Shop - Core Grinding

- Machine Shop - Metal Polishing Belt

- Machine Shop - Steel Welding

- Marine - Aluminum Welding

- Marine - Hull Building

- Metalworking - Aluminum Welding

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Misc. Operations - Mortuary Table

- Misc. Operations - Soldering

- MRO - Aluminum Welding

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Municipal & DOT Garage - Vehicle Service and Maintenance

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Aluminum Welding

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Renewable Energy Manufacturing

- Vehicle Repair - Buffing and Polishing

- Vehicle Repair - Cars & Small Trucks Repair

- Vehicle Repair - Motorcycles & ATV Repair

- Welding Shops - Aluminum Welding

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Chainsaw

Yes, but only when systems are designed, installed, and used precisely. Unlike dilution ventilation, Extraction Arms can return significant energy savings and improvements in health and safety. However, the precision at which they must be designed, installed, and used can be complex. Lev-Co uses three procedures to determine the design and installation of our extraction arms. These three procedures are OSHA HOC (hierarchy of controls), MOC (management of change), and PSR (pre-start safety review) Lev-Co recommends that these three procedures, when appropriate, should be used when selecting extraction arms as a capture method.

Here are links to examples of these three procedures:

OSHA Hierarchy of Controls

MOC Management of Change Sample Document

PSR Pre-start Health and Safety Review

Extraction Arms are essential for maintaining a safe and healthy workplace. In many benchtop applications, such as welding and soldering, where a closed-off isolation chamber is not possible, a point source capture system is needed to keep the constant stream of smoke under control.

Depending on the rate and intensity of production in your facility, the rate of fumes and smoke may rapidly increase workers' risk as a result of the volume of smoke, heat, and consistency of fumes. While some processes require minimal extraction rates, others will need high-intensity extraction capabilities. We ensure that our wide range of configurations will accommodate your specific application.

Below is a full list of processes associated with extraction arms:

- Welding, Welding Fumes, and Soldering

- Laboratories and Laboratory Fumes

- Metalworking Fumes

- Grinding

- Cutting

- Oil Mist

- Painting

- Polishing

- Packaging

- Light Dust

For more insight on configurations for welding and metal-shop, read the article below:

Welding Productivity

You can also refer to our Industry Solution Page for a list of processes.

You can find a full selection by viewing our catalog.

The configuration of an extraction system depends on many variables. The intensity of your productions process determines the rate of the accumulation of fumes, which determines the rate of airflow needed to effectively capture, which then determines the required air : cloth ratio of your filter.

How do you determine a suitable configuration?

- What contaminant are you extracting?

- What is the rate of containment accumulation per second?

- What are the physical limitations/protocols of your facility?

- How often will it be used?

Things to consider:

- Capacity: How much flow will the extraction arm handle?

- Capture Velocity: Can the extraction accommodate the required capture velocity to capture the aerosol?

- Easy to Use: How many articulations/joints does the extraction arm have?

- Stay in Place: Does the extraction stay in place, how often do the joints need to be tightened?

- Extension Hoods: Do you need a large diameter extension hood?

- e.g. 36"Ø? (Optional)

- How large is your facility? How much reach do you need?

- How many workers are working with contaminants at any given time?

- Where are fumes being extracted? Pre-defined locations, or movable workstations?

- Can the extraction arm withstand the pressure/abrasion/corrosion/etc.?

For more questions about configurations and criteria, contact us, or click the link below to get a better understanding of the importance of accurate configurations.

Welding Productivity

Pro's:

- Remove airborne toxins at source before they enter any worker's breathing zone

- Low energy costs (heat loss, electrical energy)

- Allow the use of smaller filtration equipment

- Well suited for "on-demand" controls allowing for greater flow at the source, yet lower overall flow

- Some extraction arms allow the supporting of items like wire feeders, Compressed air cord reels, and electrical cord reels for increased productivity

- Better visibility through the addition of hood-mounted lighting solutions

- Optimized hoods, large-diameter receiving hoods, and hose extensions are effective solutions where capture or hood placement is difficult

- Hood can be rotated 90° (perpendicular to the floor), eliminating shadowing

- When used correctly, the operator can visually see the contaminant being safely drawn away from the process

- Options of 115 volt means the portable filter units are effortless to install anywhere in a facility

Con's:

- Operator needs to be comfortable with the use of the arm to ensure adequate capture

- Arms not always available in larger diameters for required capture velocity

- Production time lost to place the extraction arm in place

- Cannot always reach the point of emission

- Worker buy-in is not always achieved due to a lack of fume capture

- Fugitive emission released into the workspace

- Some extractors are not built to withstand the working environment

- Poor design can lead to excess capture velocity resulting in extra capture velocity (shielding gases loss) and air noise

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

The integral flaw with dilution ventilation is the contaminants picked up by the system are not ultimately removed from the air. As a result, dilution ventilation is ineffective against most contaminants produced in industrial processes, such as metal fumes, abrasive dust, vapors, gases, and toxic chemicals. Local exhaust ventilation eliminates these issues through the capture of contaminants near or at the source of the contaminant, not allowing the contaminant to enter the breathing space, or the workplace atmosphere.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

The maintenance costs associated with our extraction arms are considerably low. Unlike some companies that construct extraction arms out of plastic and diecast white metal, all structural components of our products are made using mild/stainless steel, or aluminum.

Provided the system is adjusted correctly prior to use, and the hose is configured for your contaminant and application, these extraction arms will provide years of service with minimal maintenance.

Energy Saving:

With the use of a local exhaust ventilation system and capture at source functionality, the maintenance costs for your system will ultimately go down as a result of associated efficiency. With capture at source functionality, the area at which extraction is occurring is far smaller than the area a large duct vent would be pulling from, and as a result, far less energy is needed to complete the extraction, which runs components at lower stress levels, and boosts longevity, and reduces energy bills.

Do's:

- Use the extraction system for it's applicable contaminant

- Always refer to the manual before using the system for different contaminant

Don'ts:

- Don't use the extraction arm for incorrect applications.

- For example, if your extraction arm is configured for non-flammable contaminants, don't use it for contaminants such as VOCs

Our extraction arms come in a large range of configurations, including wall mounts, ceiling mounts, bench, and tabletop mounts. With a wide range of accessories, extraction arms can also be mounted to adjustable mounting configurations for wide span and reach.

You can find a list of Extraction Arm accessories here. For more questions about installation options, call our sales office.

Much like an extraction arm, which allows for capture-at-source fume extraction, and easy maneuverability, the Portable Filter Unit is one step up. Point source capture can be achieved anywhere you can roll the filter unit, rather than being confined to the reach of a fixed system. Quite often, “Clean Air” solutions are required throughout a workplace. These units can be easily moved from location to location with ease while capturing dust and fumes where needed.

Various Options in Filtering Systems Available:

- Washable Filters

- Cleanable Filters

- Self-Cleaning Systems

- Throw Away Filters

Portable filter units are perfect for situations where an integrated HVAC system is not an option, such as cell-based manufacturing, where workstations are being set up and torn down daily. Here is a full list:

- Aerospace - Deburring

- Aerospace - Painting and Marking

- Aerospace - Steel Welding

- Aerospace - Surface Grinders

- Art's - Jewelry Manufacturing

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Painting and Marking

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Bio & Pharma - Tablet Press Machine

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Plastic Manufacturing

- Construction - Mortar/Plaster Mixer

- Construction - Paint Spray Gun

- Dental Offices - Operating Room

- Dental Offices - Procedure Room

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Circular Automatic Buffing

- Machine Shop - Core Grinding

- Machine Shop - Manual Buffing and Polishing

- Machine Shop - Metal Polishing Belt

- Machine Shop - Metal Spinning

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Machine Shop - Straight Line Automatic Buffing

- Machine Shop - Surface Grinders

- Machine Shop - Vertical Spindle Disc Grinder

- Marine - Hull Building

- Marine - Pump Room Cleaning

- Marine - Tank Stripping

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Mining & Quarrying - Equipment Cleaning

- Mining & Quarrying - Lead Smelting

- Misc. Operations - Soldering

- MRO - Heavy Equipment Repair

- MRO - Painting and Marking

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Painting - Small Paint Booth

- Process Engineering - Rubber Calender Rolls

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Petroleum Refining

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Band Saw

- Woodworking - Chainsaw

- Woodworking - Circular Saw

Yes, but only when systems are configured, installed, and maintained for the correct use application. The filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use.

Unlike dilution ventilation, Portable Air Filer Units can return significant energy savings and improvements in health and safety. However, the precision at which they must be designed, installed, and used can be complex. Lev-co uses three procedures to determine the design and installation of our products. These three procedures are OSHA HOC (hierarchy of controls), MOC (management of change), and PSR (pre-start safety review). Lev-Co recommends that these three procedures, when appropriate, should be used when selecting Portable Air Filter Units as a capture method.

Here are links to examples of these three procedures:

OSHA Hierarchy of controls

MOC Management of change sample document

PSR Pre-start Health and Safety review

Portable air filter units are very broad in applications. Some applications include metal shops, industrial manufacturing facilities, auto shops, paint booths, and electrical repair facilities. For a full list of applicable industries, refer to our Industry Solution Page

You can find a full selection by viewing our catalog below. All units come equipped with fan/motor assemblies to ensure adequate extraction at all times.

Some important points to consider when purchasing:

- Capacity: How much flow will the extraction arm handle?

- Capture Velocity: Can the extraction accommodate the required capture velocity to capture the aerosol?

- Easy to Use: How many articulations/joints does the extraction arm have?

- Stay in Place: Does the extraction stay in place, how often do the joints need to be tightened?

- Extension Hoods: Do you need a large diameter extension hood?

- e.g. 36"Ø? (Optional)

- Can the extraction arm withstand the pressure/abrasion/corrosion/etc.?

- Can the filter withstand the pressure/abrasion/corrosion/etc.?

Pro's:

- Remove airborne toxins at source before they enter any worker's breathing zone

- Some extraction arms allow the supporting of items like wire feeders, compressed air cord reels, and electrical cord reels for increased productivity

- Better visibility through the addition of hood-mounted lighting solutions

- Optimized hoods, large-diameter receiving hoods, and hose extensions are effective solutions where capture or hood placement is difficult

- Hood can be rotated 90° (perpendicular to the floor), eliminating shadowing

- When used correctly, the operator can visually see the contaminant being safely drawn away from the process

- With the use of castors, the arm can reach far for precise fume extraction

Con's:

- Operator needs to be comfortable with the use of the arm to ensure adequate capture

- Arms not always available in larger diameters for required capture velocity

- System not effective unless configured correctly

Industrial workers are exposed to many health hazards daily. As a result, these workers risk the possibility becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

We aim to diminish that figure, but this is only possible if the correct equipment is used, and configured correctly. Our team at Lev-Co works to make the logistics of those questions as straightforward as possible, and as such, will work to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

The integral flaw with dilution ventilation is the contaminants picked up by the system are not ultimately removed from the air. As a result, dilution ventilation is ineffective against most contaminants produced in industrial processes, such as metal fumes, abrasive dust, vapors, gases, and toxic chemicals. Local exhaust ventilation eliminates these issues through the capture of contaminants near or at the source of the contaminant, not allowing the contaminant to enter the atmosphere.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

Filtration:

Filter maintenance is paramount to the healthy operation of both your workers and the fume extraction system. We offer a wide range of filter options for multiple applications. Some of these filters are washable, and as a result, reduce maintenance costs to close to zero. However, depending on shop service hours and specific contaminants, filter replacement may be required.

Electric Motor:

With the use of direct-drive motors, there are no wear items such as pulleys or belts. As a result, the risk of failure is highly unlikely, regardless of maintenance intervals.

Construction: All of our portable filter units are built with steel and are welded together for the best consistent performance, and the least leakage. As such, there is virtually nothing about the construction and function of the system that needs maintaining. The use of heavy duty ball-bearing castors ensures years of reliability on the shop floor.

Do's:

- Periodic maintenance checks

Don'ts:

- Don't obstruct the airflow

- Don't run the unit while not in use

All of our portable filter units come with built in castors for easy maneuverability and portability. There are multiple configurations of extraction arms and filters available for contaminant-specific applications.

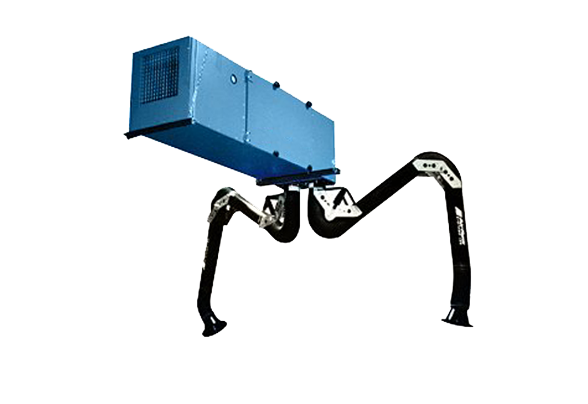

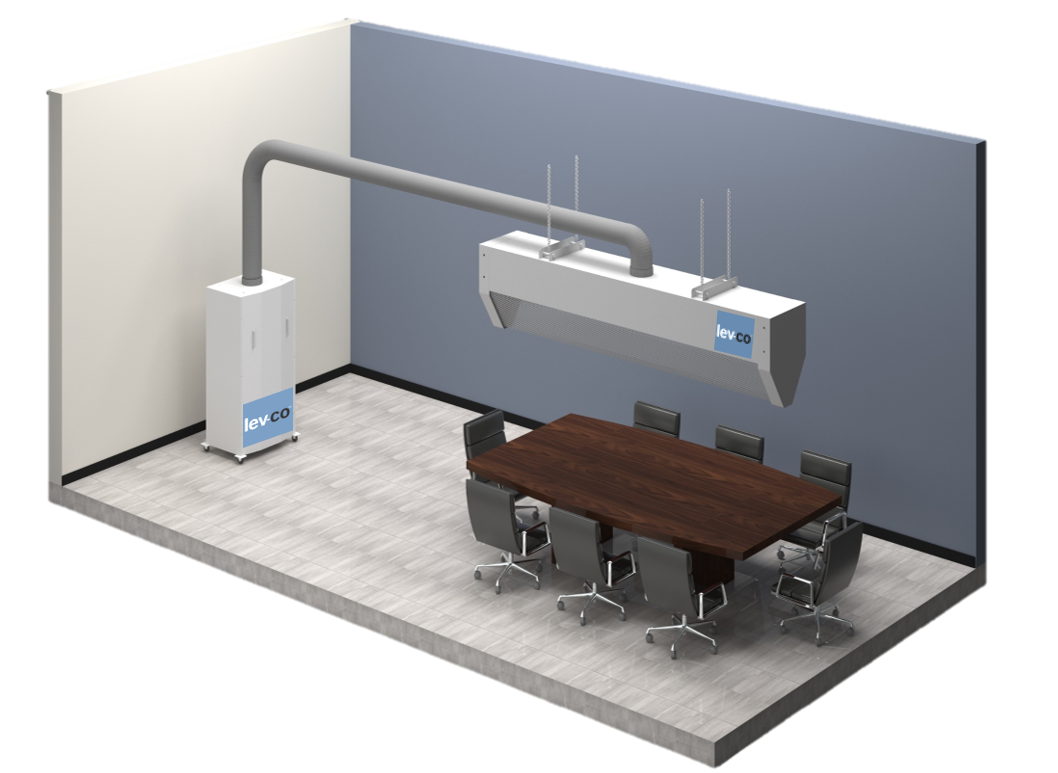

Our Single or Dual Work-Stations Filter Units are standalone or suspended systems with integrated blower and filtration. These units are designed for air recirculation as opposed to standard fume extraction, allowing for a more efficient air purification solution.

Available in several different designs:

- Ceiling mounted

- Wall mounted

- Standalone

- Portable/maneuverable

Single or Dual Work-Station Filter Units such as these are ideal for 'cell based' manufacturing and work stations. Most of these solutions are based upon self-cleaning filter cleaning systems to reduce filter costs. Water-based systems are also available for certain explosive and flammable applications.

Here is a list of applicable processes:

- Aerospace - Aluminum Welding

- Aerospace - Deburring

- Aerospace - Painting and Marking

- Aerospace - Shot Blasting

- Aerospace - Steel Welding

- Art's - Jewelry Manufacturing

- Art's - Lithography

- Auto body repair - Aluminum Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Painting and Marking

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Bio & Pharma - Tablet Press Machine

- Chemicals and Plastics - CNC Plastic Milling Machine

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Plastic Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Construction - Chainsaw

- Construction - Rock Drills

- Dental Offices - Procedure Room

- Educational - Auto Shop

- Educational - Chemistry Laboratories

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Blasting Cabinet

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Aluminum Welding

- Machine Shop - Core Grinding

- Machine Shop - Horizontal Double-Spindle Disc Grinder

- Machine Shop - Manual Buffing and Polishing

- Machine Shop - Metal Polishing Belt

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Machine Shop - Straight Line Automatic Buffing

- Machine Shop - Swing Grinder

- Machine Shop - Tumbling Mills

- Machine Shop - Vertical Spindle Disc Grinder

- Marine - Aluminum Welding

- Marine - Hull Building

- Metalworking - Aluminum Welding

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- MRO - Aluminum Welding

- MRO - Heavy Equipment Repair

- MRO - Painting and Marking

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Aluminum Welding

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Paper & Leather - Paper Strengthening

- Process Engineering - Bucket Elevator Ventilation

- Process Engineering - Rubber Calender Rolls

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Petroleum Refining

- Robotics - Robot Manufacturing

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Aluminum Welding

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Band Saw

- Woodworking - Circular Saw

- Woodworking - Jointer

- Woodworking - Mortiser

- Woodworking - Planer

- Woodworking - Radial Arm Saw

Yes, but only when systems are configured, installed, and maintained for the correct use application. The filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use. Lev-Co uses three procedures to determine the design and installation of our filter units. These three procedures are OSHA HOC (hierarchy of controls), MOC (management of change), and PSR (pre-start safety review). Lev-Co recommends that these three procedures, when appropriate, should be used when selecting filter units.

Here are links to examples of these three procedures:

OSHA Hierarchy of controls

MOC Management of change sample document

PSR Pre-start Health and Safety review

Work-station filter units serve a wide range of industrial applications. Some applications include metal shops, auto shops, manufacturing facilities, and electrical repair facilities.

Refer to our Industries Page for a full list.

For a full selection, check out our catalog below

Some important points to consider when purchasing:

- Capacity: How much flow will the filter unit handle?

- Capture Velocity: Can the filters accommodate the required capture velocity to capture the aerosol?

- Extraction Arm: Do you require point source filtration? (Optional)

- Filter Cleaning: Does the filter cleaning system really work in your application?

- Can the filters withstand the pressure/abrasion/corrosion/etc.?

- What is the Total Flow Rate? How many CFM's are needed to capture the contaminants?

- What is the exact resistance? Filter and capture device losses required for the fan to overcome?

- Do I have enough filter media in the collector? What is the air to cloth ratio?

- Will it stand up to your environment?

- e.g. is it made from plastic or steel?

- What will be my filter, maintenance and energy costs per year?

- Are there any tertiary risks such as fire, explosion, etc., that I need to consider?

Pro's:

- Ideal for cell-based manufacturing.

- Easy to relocate work stations and associated filtration equipment

- Energy savings associated with on-demand process-only filtration

- Available self-cleaning, or cleanable filters

- Available with extraction arms for point source filtration

- Straight forward installation and deployment

- Long-term cost-saving

- Not reliant on pre-existing ductwork

Con's:

- Multiple systems to maintain

- Expensive in short term

- Fixed system, cannot be moved while in use

- Limited airflow depending on filter selection

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

The integral flaw with dilution ventilation is the contaminants picked up by the system are not ultimately removed from the air. As a result, dilution ventilation is ineffective against most contaminants produced in industrial processes, such as metal fumes, abrasive dust, vapors, gases, and toxic chemicals. Local exhaust ventilation eliminates these issues through the capture of contaminants near or at the source of the contaminant, not allowing the contaminant to enter the atmosphere.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

Filtration:

Filter maintenance is paramount to the healthy operation of both your workers and the fume extraction system. We offer a wide range of filter options for multiple applications. Some of these filters are washable, and as a result, reduce maintenance costs to close to zero. However, depending on shop service hours and specific contaminants, filter replacement may be required.

Construction:

All our filter units are built with steel and are welded together for the best consistent performance, and the least leakage. As such, there is virtually nothing about the construction and function of the system that needs maintaining.

Do's:

- Maintenance checks periodically

Don'ts:

- Don't leave the unit running while not in use

- Don't obstruct the airflow

- Don't change contaminant extraction without referring to either the owners manual, or a Lev-Co representative

For fixed units, options of either wall or floor mounted configurations are available. Units can also be retrofitted to pre-existing industrial equipment.

Portable plug and play units are also available for versatile extraction.

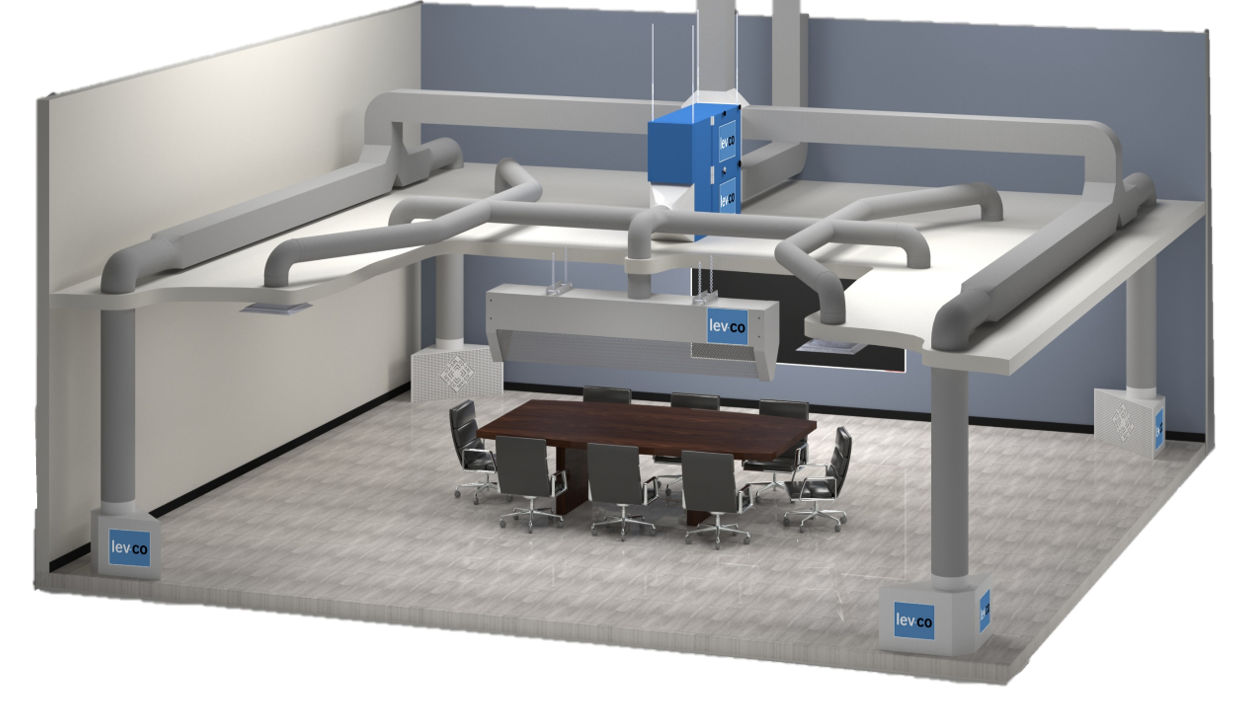

Centrally Ducted Dust Collectors such as these are ideal for large shops and centrally ducted applications. Most of these solutions are based upon self-cleaning filter cleaning systems to help reduce filter costs. In addition, Water-based filtration systems are available for certain explosive and flammable applications.

You can find a full list of suitable applications below:

- Aerospace - Shot Blasting

- Aerospace - Steel Welding

- Auto body repair - Steel Welding

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Bio & Pharma - Tablet Press Machine

- Chemicals and Plastics - CNC Plastic Milling Machine

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Blasting Cabinet

- Machine Shop - Abrasive Blasting Room

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Buffing Lathe

- Machine Shop - Horizontal Double-Spindle Disc Grinder

- Machine Shop - Metal Polishing Belt

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Machine Shop - Swing Grinder

- Machine Shop - Tumbling Mills

- Machine Shop - Vertical Spindle Disc Grinder

- Marine - Hull Building

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Mining & Quarrying - Lead Smelting

- Mining & Quarrying - Nickel Mining

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Packaging - Bin & Hopper Ventilation

- Packaging - Conveyor Belt Ventilation

- Packaging - Rail Loading

- Packaging - Toxic Material Belt Conveying Head Pulley

- Packaging - Toxic Material Conveyor Belt Loading

- Packaging - Truck Loading

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Petroleum Refining

- Robotics - Robot Manufacturing

- Waste Management - Waste Management Facilities

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Woodworking - Band Saw

- Woodworking - Jointer

- Woodworking - Mortiser

- Woodworking - Planer

- Woodworking - Radial Arm Saw

Yes, we have a large variety of configurations available to suit every application. But the local exhaust ventilation systems we supply only work when they are configured and maintained as they are designed. The correct filter selection is paramount to smoothly capturing the contaminant properly and maintaining a safe work environment.

You can find a list of suitable industries below:

- Aerospace - Shot Blasting

- Aerospace - Steel Welding

- Auto body repair - Steel Welding

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Bio & Pharma - Tablet Press Machine

- Chemicals and Plastics - CNC Plastic Milling Machine

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Blasting Cabinet

- Machine Shop - Abrasive Blasting Room

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Buffing Lathe

- Machine Shop - Horizontal Double-Spindle Disc Grinder

- Machine Shop - Metal Polishing Belt

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Machine Shop - Swing Grinder

- Machine Shop - Tumbling Mills

- Machine Shop - Vertical Spindle Disc Grinder

- Marine - Hull Building

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Mining & Quarrying - Lead Smelting

- Mining & Quarrying - Nickel Mining

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Packaging - Bin & Hopper Ventilation

- Packaging - Conveyor Belt Ventilation

- Packaging - Rail Loading

- Packaging - Toxic Material Belt Conveying Head Pulley

- Packaging - Toxic Material Conveyor Belt Loading

- Packaging - Truck Loading

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Petroleum Refining

- Robotics - Robot Manufacturing

- Waste Management - Waste Management Facilities

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Woodworking - Band Saw

- Woodworking - Jointer

- Woodworking - Mortiser

- Woodworking - Planer

- Woodworking - Radial Arm Saw

You can view our products in our catalog below.

Some important points to consider when purchasing:

- Velocity: What velocity is needed to pick up the contaminant?

- Filter Media: What is the air : cloth ratio required for consistent filtration for your application?

- Maintenance Costs: How often will the filter need to be washed/replaced?

- Are there any tertiary risks such as fire, explosion, etc., that I need to consider?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Pros:

- High volume for larger application

- Industrial design

- Modular

- Single units serve multiple workstations

- Self-contained

- Covers large range of contaminants

Cons:

- Fixed position

- Installation

The integral flaw with dilution ventilation is that the contaminant picked up by the process ultimately stays airborne. Dilution ventilation picks up the contaminant and dilutes it with clean air, but doesn't remove the contaminant from the air until it has spread through the building to the exhaust system. As a result of this, dilution ventilation is not suitable for industrial processes. The contaminants produced in industrial process include toxic fumes, metal dust, oil mist, vapors, and gases.

Local exhaust ventilation is a much more effective extraction process that utilizes methods that capture the contaminant near or at the source of process. This eliminates the possibility of airborne contaminants entering the breathing zone. Rather than invest money into the buildings ventilation system to cope with the contaminant, simply invest in what will remove the risk all together.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

Construction:

Our units are built using only raw materials like steel and aluminum. This ensures a long lasting product that won't fail from fatigue of plastic or die-cast elements. We also finish our products in a durable polyurethane finish which designed to cope with harsh environments, reducing the risk of corrosion.

Filters:

Our filter units incorporate a "Vibra-Pulse" filter cleaning system that reduces maintenance costs dramatically when compared to conventional filtration designs. We also offer a HEPA high efficiency after-filter to deliver 99.97% filter efficiency.

Electric Motor:

All of our units incorporate an electric direct-drive motor. Without the use of pulleys or belts, the maintenance associated with the motor is all but non-existent.

Sometimes the best solution for extracting welding fumes is right on the table. This is generally referred to as a Down Draft Table. The Downdraft Table serves as both a workbench and an air cleaner. A rigid grill supports the product, while an air cleaner below draws smoke and fumes down and away from the worker's breathing zone. A worker can weld, grind, and cut on the surface of the table while dust and fumes get sucked away from breathing air space.

By combining the extraction system with a workbench, downdraft tables are very effective for safe work environments, and space-saving solutions. Soldering, spray-painting, and other benchwork applications are exactly what our downdraft tables are for.

- Aerospace - Aluminum Welding

- Aerospace - Deburring

- Aerospace - Painting and Marking

- Aerospace - Steel Welding

- Art's - Cleaning with Solvents and VOC's

- Art's - Jewelry Manufacturing

- Auto body repair - Aluminum Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Painting and Marking

- Auto body repair - Steel Welding

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Construction - Paint Spray Gun

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Aluminum Welding

- Machine Shop - Hand Grinding Bench

- Machine Shop - Metal Polishing Belt

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Marine - Aluminum Welding

- Metalworking - Aluminum Welding

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Misc. Operations - Mortuary Table

- MRO - Aluminum Welding

- MRO - Heavy Equipment Repair

- MRO - Painting and Marking

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Aluminum Welding

- National Defense - Ammunition Manufacturing

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Painting - Small Paint Booth

- Paper & Leather - Paper Strengthening

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Aluminum Welding

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

Yes, but only when systems are configured, installed, and maintained for the correct use application. The filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use.

Downdraft tables are mainly designed with the idea of a workstation being integrated into the unit, so any application that requires fume extraction from a bench is ideal for a downdraft table. This includes soldering, grinding, spray painting, and welding. For a full list of industries, refer to our Industry Solution Page

To see a full list of products, check out our catalog below.

Some important points to consider when purchasing:

- Air Velocity: What is the velocity or the air required to pull the fumes and dust down into the table? (Add up the CFM for all of the inlets that will run at once)

- Face Velocity: What is the velocity at the Table surface required to achieve the appropriate capture velocity?

- Noise: Does your facility require a low operation noise level?

- Portability: Do you need the ability to reposition or maneuver the table?

- Orientation: Do you work standing up, or sitting down?

- Filter Cleaning: Does the filter cleaning system really work in your application?

- Surface Area: How much space to you need for your application?

- Capture Velocity: Can the filters accommodate the required capture velocity to capture the aerosol?

- Can the filters withstand the Pressure/abrasion/corrosion/etc.?

- Do I have enough filter media (air to cloth ratio) in the collector?

- Will it stand up to the working environment?

- e.g. is it made from plastic or steel?

- What will be my filter, maintenance, and energy costs per year?

- Are there any tertiary risks such as fire, explosion, etc., that I need to consider?

Pro's:

- Portable options available

- Commercial options available

- Multi-purpose - doubles as a standard work-bench

- All steel construction

- Easy filter access - reduces maintenance time

- Multiple filter options

Con's

- Extraction is restricted to the bench surface

- Portability of the unit determines the range of extraction

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Dilution ventilation is designed with more of a commercial aspect in mind. As oppose to local exhaust ventilation, how dilution ventilation extracts contaminants is by diluting them with fresh air, which requires the contaminants to be airborne before being removed from the building. This means that all airborne contaminants ultimately spread throughout the building until being pushed through the ventilation exhaust system.

On the other hand, local exhaust ventilation captures contaminants at or near the source of the process. This eliminates the possibility of the contaminant becoming airborne in the first place. Eliminating the risk of airborne contaminant means that a buildings HVAC system does not have to filter industrial contaminants, which dilution ventilation is not designed to do. Some industrial contaminants are highly abrasive and corrosive. Rather than investing in the maintenance costs of the building multiple times, invest in the engineering control solution designed to deal with it.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

Our downdraft tables are all built using only mild and stainless steel, and finished in a very durable polyurethane powder coating, powered by a direct drive electric motor. We follow these requirements to ensure long life and minimal maintenance costs.

Filters:

We offer a selection of several filters, each designed for different workloads. Depending on contaminant, hours of use, and hazards associated with any given contaminant, we have a filter that will work for your needs. This way you don't need to worry about filters clogging prematurely, which avoids premature failure.

Motors: We use a direct drive motor on all of our extraction systems. Without the use of belts or pulleys in the driveline of the motor, associated maintenance costs are substantially lower, and allow you to get the most use out of your system without service intervals.

Back and Side Draft Tables are similar to Down-Draft Tables. “Back Draft” and “Cross Draft” are ideal solutions when extraction methods such as self-supporting extraction arms and other such systems prove to be inappropriate for the application. The contaminated air is drawn in from the back or side panels of the work area. These units come with or without filtration systems and can also be combined to create complete enclosures for whatever the application might be.

- Aerospace - Deburring

- Aerospace - Painting and Marking

- Aerospace - Steel Welding

- Art's - Acid Etching

- Art's - Cleaning with Solvents and VOC's

- Art's - Jewelry Manufacturing

- Art's - Screen Printing

- Art's - Stained Glass

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Painting and Marking

- Auto body repair - Steel Welding

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Forensics - Forensic Laboratories

- Machine Shop - Steel Welding

- Metalworking - Steel Welding

- Misc. Operations - Mortuary Table

- MRO - Heavy Equipment Repair

- MRO - Painting and Marking

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Painting - Dip Tank

- Paper & Leather - Paper Strengthening

- Public Transportation - Subway Maintenance and Repair

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

yes, our collection systems are very effective. However, correct configuration is paramount in guaranteeing the unit performs as it should. Our goal is to make it as easy as can be to configure your system to your specific needs, and our sales representatives are happy to help you along the way to buying the right product.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Some important points to consider when purchasing:

- Air Velocity: What is the velocity or the air required to pull the fumes and dust horizontally into the table?

- Capture Velocity: Add up the CFM for all of the inlets that will run at once

- Face Velocity: What velocity at the table surface is required to achieve the appropriate capture velocity?

- Filter Cleaning: Does the filter cleaning system really work in your application?

- Do I have enough filter media in the collector? (air to cloth ratio)

- Will it stand up to the working environment?

- e.g. is it made from plastic or steel?

- What will be my filter maintenance and energy costs per year?

- Are there any tertiary risks such as fire, explosion, etc., that I need to consider?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

We are dedicated to diminishing that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of these questions as straightforward and coherent as possible. We will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

These units are designed to capture airborne contaminants such as oil mist and chemicals, while simultaneously extracting and containing dust and moisture created by the machining process. Our units use filters that are "SELF-DRAINING", which captures moisture, and dust at the same time, and as such, it is very important that the amount of dust being captured by these systems does not exceed more than 5% of the total extracted pollutant. If the dust quantity is kept to a minimum, filter life can be expected between 1 to 5 years depending on the application and runtime.

Mist Collectors are for a variety of mist-producing applications such as CNC machining and cold-heading applications. A full list of applications can be found below:

Yes, these units can make the workplace safer by capturing harmful oil mists that otherwise mix with the air in industrial facilities. However, the effectiveness of our units relies on proper configuration, installation, and maintenance for the specific application. We offer a range of configurations that vary from standalone extraction systems with point source extraction, to integrated systems that extract directly from the machining process.

Our mist collectors are designed for precision metalwork applications, such as CNC machining, cold-heading, and lathing applications.

To see our selection of products, check out our catalog below

Some important points to consider when purchasing:

- Velocity: How much airflow is needed to pick up the contaminant?

- Point-Source or Integrated System: Do you need to extract from a workstation, or from a machining process?

- Portability: Do you need mist collection from multiple workstations, or integrated installation?

- Filter Selection: What filter do you need for your contaminant?

- Positioning: Do you need an extraction arm to capture your source more effectively?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It is our goal to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the process of answering your questions as straightforward and coherent as possible, and as such, will work with you to provide you with the system that best fits your needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Mist:

- Capture Velocity 100 FPM

- Transport Velocity 2250 FPM

- Minimum Face Velocity 1766 FPM

Here are some general design velocities when using "ENCLOSING" Hoods:

Mist CNC:

- Minimum Face Velocity 75 FPM

- Transport Velocity 2250 FPM

Environmental Control Booths allow operators to work on a variety of components while assuring worker comfort and visibility within the critical area. These solutions also ensure that the "dust produced within the booth... stays in the booth..."

- Aerospace - Deburring

- Aerospace - Steel Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Chemicals and Plastics - Pesticide Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Steel Welding

- Forensics - Forensic Laboratories

- Machine Shop - Steel Welding

- Metalworking - Steel Welding

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- National Defense - Steel Welding

- Painting - Small Paint Booth

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Chainsaw

Yes, but only when the system is configured, installed, and maintained for the correct application. The filter selection is the most important decision for ensuring the reliability, effectiveness, and safety of the unit you select.

For a full list of industries, refer to our Industry Solution Page.

For a list of available models, check out our catalog below.

Some important points to consider when purchasing:

- Filter Cleaning: Is it easy to clean? Does the filter cleaning system really work?

- How large does the booth have to be?

- Is the air speed through the work zone high enough to protect the worker?

- What is the noise level? Inside and outside the booth?

- Will it stand up to your environment?

- e.g. is it made from plastic or steel?

- What will be my filter costs per year? - In welding you can use lbs. of welding wire…

- What is the filtration efficiency?

- Are there any tertiary risks such as fire, explosion, etc.?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured accordingly. Our team works to make the process of answering those questions as straightforward and coherent as possible, and will work to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Ambient Air Cleaners involve the use of large “Washable, Cleanable or Replaceable Media” filters. These units both filter and re-circulate the air back into the work place.

Installation Configurations:

- Free Hanging “Negative Pressure”

- “Race Track”

- "Cross Dilution"

Depending upon the designed air pattern, these systems "scrub" the ambient air of contaminants, and the result is a dramatic reduction of airborne pollution. These systems are best used in combination with source-collection equipment.

- Aerospace - Deburring

- Aerospace - Steel Welding

- Apparel & Clothing - Clothing Assembly Line

- Apparel & Clothing - Textile Dyeing

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Chemicals and Plastics - Pesticide Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Electronics - 3D Printing

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Machine Shop - Steel Welding

- Metalworking - Steel Welding

- Misc. Operations - 3D Printing

- Misc. Operations - Cigarette and Tobacco Smoke

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Paleontology

- National Defense - Indoor Pistol and Small Bore Rifle Range Ventilation

- National Defense - Steel Welding

- Robotics - 3D Printing

- Vehicle Repair - Buffing and Polishing

- Waste Management - Waste Management Facilities

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

Yes, but only when systems are configured, installed, and maintained for the correct use application. The filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Some important points to consider when purchasing:

- What is the volume of the room you want to clean?

- e.g. cubic dimension: L'xW'xH'

- How many times would you like to change the air in your room?

- e.g. Welding=8 AC/H

- How much contaminant do I generate?

- e.g. dust, smoke, fume

- Where am I going to mount these units?

- Can I use these units to create a negative pressure in my work area?

- Do I want "throw away", "washable", "cleanable" or "self cleaning" filters?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Ducted Air Cleaners are used in a variety of applications where the filter selection often requires a specific configuration. With these collectors, you can select a variety of particulate, liquid or gas phase filters such as “HEPA” filters, “Mist Agglomerators”, and “Gas Absorbers” respectively. These systems are available with or without pre-engineered and installed fan packages.

Here are some general design velocities when using "CAPTURE" Hoods:

Smoke (e.g. Welding):

- Capture Velocity 100 FPM

- Transport Velocity 3000 FPM

- Minimum Face Velocity 2355 FPM

Dust (e.g. Grinding):

- Capture Velocity 500 FPM

- Transport Velocity 4000 FPM

- Minimum Face Velocity 4000 FPM

Gas (e.g. V.O.C.'s):

- Capture Velocity 50 FPM

- Transport Velocity 2000 FPM

- Minimum Face Velocity 785 FPM

Mist:

- Capture Velocity 100 FPM

- Transport Velocity 2250 FPM

- Minimum Face Velocity 1766 FPM

- Aerospace - Deburring

- Aerospace - Steel Welding

- Aerospace - Surface Grinders

- Apparel & Clothing - Clothing Assembly Line

- Apparel & Clothing - Textile Dyeing

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Chemicals and Plastics - Pesticide Manufacturing

- Educational - Machine Shop

- Educational - Welding Shop

- Electronics - 3D Printing

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Steel Welding

- Machine Shop - Surface Grinders

- Metalworking - Steel Welding

- Mining & Quarrying - Lead Smelting

- Misc. Operations - 3D Printing

- Misc. Operations - Cigarette and Tobacco Smoke

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Paleontology

- National Defense - Indoor Pistol and Small Bore Rifle Range Ventilation

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Robotics - 3D Printing

- Vehicle Repair - Buffing and Polishing

- Waste Management - Waste Management Facilities

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

Yes, but only when systems are configured, installed, and maintained for the correct use application. Choosing the right filter is essential for ensuring the reliability, effectiveness, and safety of your unit.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

This is our mission, but it will only succeed if we use and configure the right equipment. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Updraft and Overhead hoods, completely or partially enclose the process or contaminant generation point.

For example:

A Complete Enclosure would be a sealed “box” or similar type of configuration where only minimal openings exist and the contaminated air is sucked up and away. The enclosing hood is preferred wherever the process configuration and operation will permit.

A Partial Enclosure would be an “open box” (i.e.: with the lid cut off). An inward flow of air through the enclosure opening will contain the contaminant within the enclosure and prevent its escape into the outside work environment.

If a complete enclosure is not feasible, the partial enclosure should be used to the maximum extent possible.

- Aerospace - Steel Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Steel Welding

- Chemicals and Plastics - Rubber Manufacturing

- Educational - Welding Shop

- Farm & Heavy Equipment - Steel Welding

- Machine Shop - Steel Welding

- Metalworking - Steel Welding

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- National Defense - Steel Welding

- Vehicle Repair - Buffing and Polishing

- Waste Management - Waste Management Facilities

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

Yes it will, but only when systems are set up and maintained for the correct application. Filter selection is the most important variable to ensuring the reliability, effectiveness, and safety of the unit you use.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured for the right contaminant. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Mobile HEPA vacuums and hi-vacuum/pressure dust collectors, designed for tough industrial applications. We use a variety of filtration stages.

Example: Pre-separators, pre-filters, spark traps, cleanable or self-cleaning main filter, HEPA filters, and VOC/ODOUR control final filters. Certified Leak tested HEPA filters are tested for effectiveness and safety of the personnel using the equipment.

- Aerospace - Steel Welding

- Aerospace - Surface Grinders

- Auto body repair - Buffing and Polishing

- Auto body repair - Steel Welding

- Construction - Concrete Demolition Hammer

- Construction - Concrete Floor Grinder/Polisher

- Educational - Auto Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Food Packaging Plant

- Machine Shop - Bandsaw

- Machine Shop - Manual Buffing and Polishing

- Machine Shop - Steel Welding

- Machine Shop - Surface Grinders

- Metalworking - Chip Collection

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Mining & Quarrying - LongWall Mining

- Misc. Operations - Other

- Misc. Operations - Soldering

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- National Defense - Steel Welding

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Steel Welding

Yes, but only if the system is configured, installed, and maintained for the correct use. Proper filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to consistently reduce that figure, but it only works if the correct equipment is used. Our team works to make choosing the right product as straightforward and coherent as possible, and as such, will work with you to deliver the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

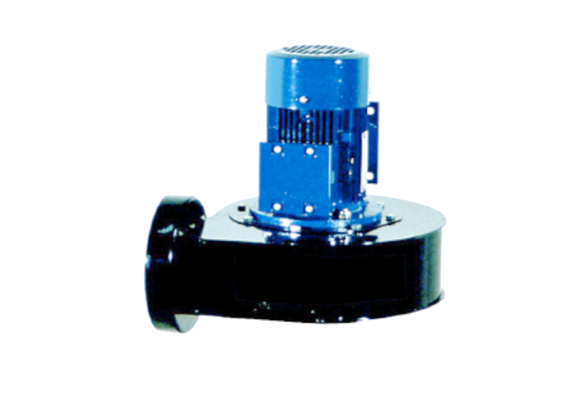

Fans for air make up and exhaust are quite often a difficult product to find when designing a simple ducted local exhaust system.

Here we offer a variety of "LEV" (Local Exhaust and Ventilation) fans specifically designed to meet the demands of such systems.

These Fans are able to handle specific applications such as:

- Corrosive Fumes

- Abrasive Dusts

- Proper Flow and Static Pressure for a particular application.

Please feel free to contact one of our System Design Technicians for help in selecting the right fan for your application.

- Aerospace - Steel Welding

- Art's - Cleaning with Solvents and VOC's

- Auto body repair - Steel Welding

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Rubber Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Construction - Concrete Demolition Hammer

- Educational - Auto Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Canning

- Food & Beverage - Food Packaging Plant

- Food & Beverage - Fruit Production

- Food & Beverage - Refrigeration

- Forensics - Forensic Laboratories

- Machine Shop - Steel Welding

- Machine Shop - Straight Line Automatic Buffing

- Marine - Hull Building

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- Mining & Quarrying - Lead Smelting

- Mining & Quarrying - Nickel Mining

- Misc. Operations - Cigarette and Tobacco Smoke

- Misc. Operations - Mortuary Table

- MRO - Diesel Engines Repair

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Painting - Dip Tank

- Painting - Drying Oven Ventilation

- Painting - Large Paint Booth

- Painting - Paint Mix Storage Room

- Painting - Trailer Interior Spray Painting

- Paper & Leather - Paper Bleaching

- Paper & Leather - Paper Pulping

- Process Engineering - Air Cooled Mixer and Muller

- Process Engineering - Banbury Mixer

- Process Engineering - Bucket Elevator Ventilation

- Process Engineering - Mixer And Muller Hood

- Process Engineering - Roller Mill Ventilation

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Public Transportation - Train Maintenance and Repair

- Refineries & Energy - Renewable Energy Manufacturing

- Robotics - Robot Manufacturing

- Vehicle Repair - Cars & Small Trucks Repair

- Vehicle Repair - Diesel Engines Repair

- Vehicle Repair - Truck Repair

- Waste Management - Vehicle Repair Garage

- Welding Shops - Steel Welding

- Woodworking - Wood Briquetting

- Woodworking - Wood Incineration

Yes, when correctly configured, our extraction systems will work for years without issue, and will greatly improve the air quality of your facility. We have sales engineers ready to answer your questions to ensure you get the product you need.

For a full list of industries, refer to our Industry Solution Page

For a list of available models, check out our catalog below.

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It is our mission to reduce that figure, but only if the right equipment is used and configured properly. As part of our comprehensive customer service, we are dedicated to making the logistics of those questions as straightforward and coherent as possible, and as such will collaborate with you to ensure the best extraction system for your workers. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

Vehicle exhaust produces harmful carbon emissions. When engines are operated indoors, the risk of consuming those emissions is very high without an extraction solution.

We offer a range of products that offer capture-at-source extraction to minimize the risk often posed by mechanics shops and diesel garages. Our systems are designed to clamp directly to the exhaust system of any vehicle, removing the risk of injury or fire related to the heat of the vehicle exhaust system.

- Emergency Services - Ambulance Services

- Emergency Services - Fire Stations

- Emergency Services - Police Services

- Marine - Outboard Motor Test

- MRO - Diesel Engines Repair

- Municipal & DOT Garage - Vehicle Service and Maintenance

- National Defense - Military Vehicle Repair

- Painting - Small Paint Booth

- Paper & Leather - Leather Tanning

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Public Transportation - Train Maintenance and Repair

- Vehicle Repair - Cars & Small Trucks Repair

- Vehicle Repair - Diesel Engines Repair

- Vehicle Repair - Motorcycles & ATV Repair

- Vehicle Repair - Truck Repair

- Waste Management - Vehicle Repair Garage

- Waste Management - Waste Management Facilities

Yes, this solution can make the workplace safer by capturing the toxic emissions at the source.

This process involves 3 steps:

- Capture of the gases at source through suction nozzles

- Transporting the gases through exhaust hoses to an exhaust fan

- Transport the gases to the atmosphere.

Suitable industries include automotive, mining, and transportation.

For a list of available models, check out our catalog below.

Below is a list of the information that needs to be gathered prior to selecting the appropriate VEHICLE EXHAUST ventilation system:

- Max Engine HP/RPM: How much pressure does your exhaust system produce at idle?

- Engine being run A - under load? or B - at idle?

- Diameter of smallest and largest tailpipes? Do you require multiple fitments?

- Configuration of tailpipes?

- e.g. are they exposed, behind a grill, overhead stack, undercarriage, etc…?

- Voltage and Amperage available

- Fixed or Portable system?