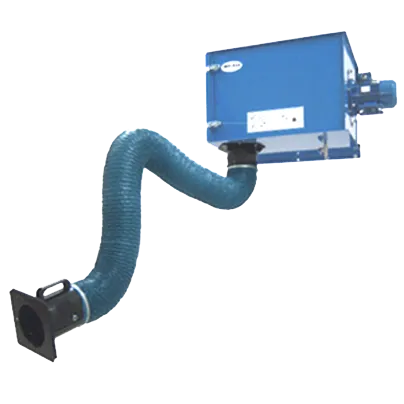

Wall/Floor Mounted Filters

Our Single or Dual Work-Stations Filter Units are standalone or suspended systems with integrated blower and filtration. These units are designed for air recirculation as opposed to standard fume extraction, allowing for a more efficient air purification solution.

Available in several different designs:

- Ceiling mounted

- Wall mounted

- Standalone

- Portable/maneuverable

Single or Dual Work-Station Filter Units such as these are ideal for 'cell based' manufacturing and work stations. Most of these solutions are based upon self-cleaning filter cleaning systems to reduce filter costs. Water-based systems are also available for certain explosive and flammable applications.

Here is a list of applicable processes:

- Aerospace - Aluminum Welding

- Aerospace - Deburring

- Aerospace - Painting and Marking

- Aerospace - Shot Blasting

- Aerospace - Steel Welding

- Art's - Jewelry Manufacturing

- Art's - Lithography

- Auto body repair - Aluminum Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Painting and Marking

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Bio & Pharma - Tablet Press Machine

- Chemicals and Plastics - CNC Plastic Milling Machine

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Plastic Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Construction - Chainsaw

- Construction - Rock Drills

- Dental Offices - Procedure Room

- Educational - Auto Shop

- Educational - Chemistry Laboratories

- Educational - Machine Shop

- Educational - Welding Shop

- Educational - Wood Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Farm & Heavy Equipment - Steel Welding

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Food Packaging Plant

- Forensics - Forensic Laboratories

- Machine Shop - Abrasive Blasting Cabinet

- Machine Shop - Abrasive Cut-Off Saw

- Machine Shop - Aluminum Welding

- Machine Shop - Core Grinding

- Machine Shop - Horizontal Double-Spindle Disc Grinder

- Machine Shop - Manual Buffing and Polishing

- Machine Shop - Metal Polishing Belt

- Machine Shop - Portable Chipping and Grinding Table

- Machine Shop - Steel Welding

- Machine Shop - Straight Line Automatic Buffing

- Machine Shop - Swing Grinder

- Machine Shop - Tumbling Mills

- Machine Shop - Vertical Spindle Disc Grinder

- Marine - Aluminum Welding

- Marine - Hull Building

- Metalworking - Aluminum Welding

- Metalworking - Steel Welding

- Mining & Quarrying - Drilling

- MRO - Aluminum Welding

- MRO - Heavy Equipment Repair

- MRO - Painting and Marking

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Aluminum Welding

- National Defense - Military Vehicle Repair

- National Defense - Steel Welding

- Paper & Leather - Paper Strengthening

- Process Engineering - Bucket Elevator Ventilation

- Process Engineering - Rubber Calender Rolls

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Petroleum Refining

- Robotics - Robot Welding

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Aluminum Welding

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Band Saw

- Woodworking - Circular Saw

- Woodworking - Jointer

- Woodworking - Mortiser

- Woodworking - Planer

- Woodworking - Radial Arm Saw

Yes, but only when systems are configured, installed, and maintained for the correct use application. The filter selection is paramount to ensuring the reliability, effectiveness, and safety of the unit you use. Lev-Co uses three procedures to determine the design and installation of our filter units. These three procedures are OSHA HOC (hierarchy of controls), MOC (management of change), and PSR (pre-start safety review). Lev-Co recommends that these three procedures, when appropriate, should be used when selecting filter units.

Here are links to examples of these three procedures:

OSHA Hierarchy of controls

MOC Management of change sample document

PSR Pre-start Health and Safety review

Work-station filter units serve a wide range of industrial applications. Some applications include metal shops, auto shops, manufacturing facilities, and electrical repair facilities.

Refer to our Industries Page for a full list.

For a full selection, check out our catalog below

Some important points to consider when purchasing:

- Capacity: How much flow will the filter unit handle?

- Capture Velocity: Can the filters accommodate the required capture velocity to capture the aerosol?

- Extraction Arm: Do you require point source filtration? (Optional)

- Filter Cleaning: Does the filter cleaning system really work in your application?

- Can the filters withstand the pressure/abrasion/corrosion/etc.?

- What is the Total Flow Rate? How many CFM's are needed to capture the contaminants?

- What is the exact resistance? Filter and capture device losses required for the fan to overcome?

- Do I have enough filter media in the collector? What is the air to cloth ratio?

- Will it stand up to your environment?

- e.g. is it made from plastic or steel?

- What will be my filter, maintenance and energy costs per year?

- Are there any tertiary risks such as fire, explosion, etc., that I need to consider?

Pro's:

- Ideal for cell-based manufacturing.

- Easy to relocate work stations and associated filtration equipment

- Energy savings associated with on-demand process-only filtration

- Available self-cleaning, or cleanable filters

- Available with extraction arms for point source filtration

- Straight forward installation and deployment

- Long-term cost-saving

- Not reliant on pre-existing ductwork

Con's:

- Multiple systems to maintain

- Expensive in short term

- Fixed system, cannot be moved while in use

- Limited airflow depending on filter selection

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

The integral flaw with dilution ventilation is the contaminants picked up by the system are not ultimately removed from the air. As a result, dilution ventilation is ineffective against most contaminants produced in industrial processes, such as metal fumes, abrasive dust, vapors, gases, and toxic chemicals. Local exhaust ventilation eliminates these issues through the capture of contaminants near or at the source of the contaminant, not allowing the contaminant to enter the atmosphere.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

Filtration:

Filter maintenance is paramount to the healthy operation of both your workers and the fume extraction system. We offer a wide range of filter options for multiple applications. Some of these filters are washable, and as a result, reduce maintenance costs to close to zero. However, depending on shop service hours and specific contaminants, filter replacement may be required.

Construction:

All our filter units are built with steel and are welded together for the best consistent performance, and the least leakage. As such, there is virtually nothing about the construction and function of the system that needs maintaining.

Do's:

- Maintenance checks periodically

Don'ts:

- Don't leave the unit running while not in use

- Don't obstruct the airflow

- Don't change contaminant extraction without referring to either the owners manual, or a Lev-Co representative

For fixed units, options of either wall or floor mounted configurations are available. Units can also be retrofitted to pre-existing industrial equipment.

Portable plug and play units are also available for versatile extraction.

_-_SingleDual_Work-Station_Filter_Unit_696/WF-SCF_PrimaryImage_500.jpeg)

.png%20007.png)