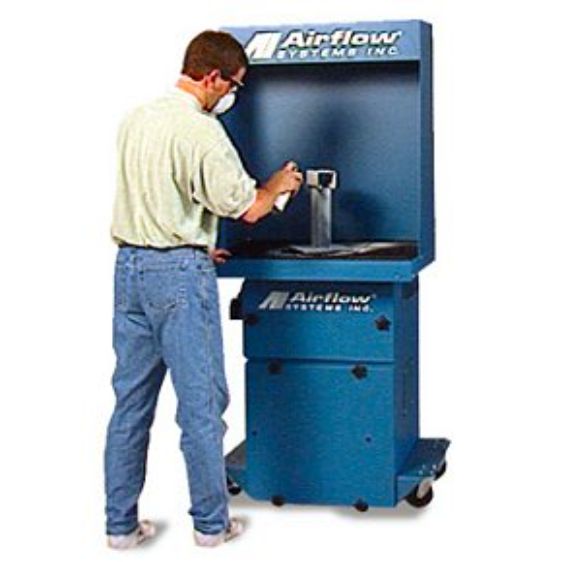

Dust Control Booths

Environmental Control Booths allow operators to work on a variety of components while assuring worker comfort and visibility within the critical area. These solutions also ensure that the "dust produced within the booth... stays in the booth..."

- Aerospace - Deburring

- Aerospace - Steel Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Deburring

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Chemicals and Plastics - Pesticide Manufacturing

- Educational - Auto Shop

- Educational - Machine Shop

- Educational - Welding Shop

- Farm & Heavy Equipment - Steel Welding

- Forensics - Forensic Laboratories

- Machine Shop - Steel Welding

- Metalworking - Steel Welding

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Steel Welding

- National Defense - Steel Welding

- Painting - Small Paint Booth

- Vehicle Repair - Buffing and Polishing

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Chainsaw

Yes, but only when the system is configured, installed, and maintained for the correct application. The filter selection is the most important decision for ensuring the reliability, effectiveness, and safety of the unit you select.

For a full list of industries, refer to our Industry Solution Page.

For a list of available models, check out our catalog below.

Some important points to consider when purchasing:

- Filter Cleaning: Is it easy to clean? Does the filter cleaning system really work?

- How large does the booth have to be?

- Is the air speed through the work zone high enough to protect the worker?

- What is the noise level? Inside and outside the booth?

- Will it stand up to your environment?

- e.g. is it made from plastic or steel?

- What will be my filter costs per year? - In welding you can use lbs. of welding wire…

- What is the filtration efficiency?

- Are there any tertiary risks such as fire, explosion, etc.?

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured accordingly. Our team works to make the process of answering those questions as straightforward and coherent as possible, and will work to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO