Portable HEPA Filters - Large Spaces

1. What is Covid 19?

Coronavirus disease (COVID-19) is an infectious disease caused by a newly discovered coronavirus.

2. What are the Covid-19 health concerns around aerosol spread?

Scientists and researchers are continually gathering new evidence about this disease, including routes of transmission. New data suggests that it is possible for COVID-19 to spread through the air among people who are in enclosed, crowded spaces with poor ventilation for a prolonged period of time. Factors contributing to the transmission may include activities that cause heavy breathing, such as singing, dancing or exercise, especially without precautions such as wearing a mask or keeping a physical distance. However, close, person-to-person contact with an infected person before they show symptoms remains the most common method of transmission.

3. Can mechanical air filtration systems make indoor spaces safe from Covid-19?

If you are in a room that can’t get enough outside air for dilution, consider an air cleaner, also commonly called air purifiers. These machines remove particles from the air, usually using a filter made of tightly woven fibers. They can capture particles containing bacteria and viruses and can help reduce disease transmission.

The U.S. Environmental Protection Agency says that air cleaners can do this for the coronavirus, but not all air cleaners are equal. Before you go out and buy one, there are few things to keep in mind.

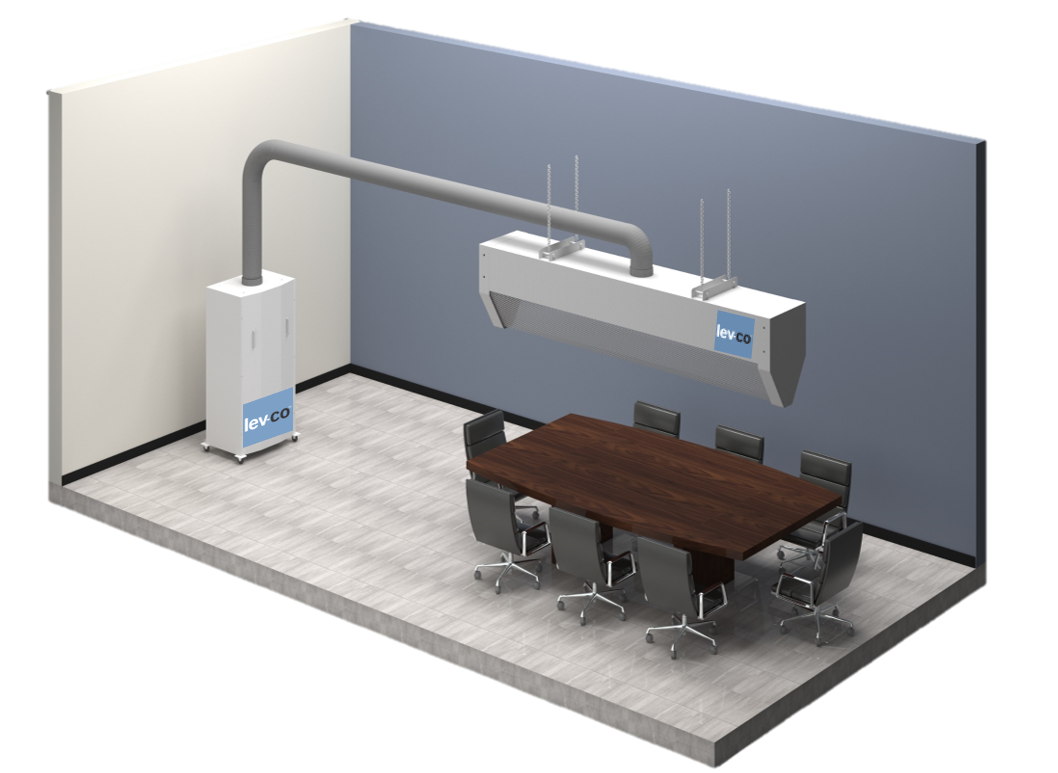

In light of the WHO's confirmation that there is "emerging evidence" of airborne transmission of Coronavirus Lev-co has put together a series of products that may assist you in designing and procuring solutions that limit the spread of airborne particles such as the coronavirus. In this section you will find equipment that addresses each of these components required in a ventilation system tailored to capture and filter and return air to your facility.

4. What do the health experts say?

The EPA says: " When used properly, air cleaners and HVAC filters can help reduce airborne contaminants including viruses in a building or small space. By itself, air cleaning or filtration is not enough to protect people from exposure to the virus that causes COVID-19. When used along with other best practices recommended by CDC and others, filtration can be part of a plan to reduce the potential for airborne transmission of COVID-19 indoors."

5. How do different systems work and what are the practical and health concerns?

See our list of Control measures listed below, Please note, the practical and health concerns are listed within each CM.

6. What are the common components of a Covid-19 Ventilation system?

See Below:

- Supply Air diffusers and/or Nozzles to direct the clean air to the occupant

- Transport ducts and hoses

- Powered and non-powered filter housings and air cleaners

- Electrical controls (VFD and differential Pressure controls)

- Booster fans (Optional)

- Capture devices

7. In what kind of environments can mechanical air filtration systems be most effective?

The environments that are best suited for mechanical ventilation are:

- Nursing homes

- Fitness clubs

- Restaurants and bars

- Meeting rooms

- Lunchrooms and cafeterias

8. What are the pros and cons of Local Exhaust Ventilation versus HVAC solutions? Are there any other possible solutions?

Local Exhaust Ventilation is best suited to the control and filtration of the covid virus because it controls the virus at source and directs the virus aerosol to the filter unit, typically before it can be inhaled by another person where HVAC simply mixes or dilutes the contaminated air allowing other persons to breathe the air in before the air is filtered from the virus.

Here is a link to our NEW respirable hazards Page:

Covid-19 and ventilation, everything you need to know!

Here are a few links to articles written about the capture and control of Covid-19 emissions:

Here is a link to our NEW respirable hazards Page:

Covid-19 and ventilation, everything you need to know!

Here are a few links to articles written about the capture and control of Covid-19 emissions:

- U.S. Department of Labor: COVID-19 - Control and Prevention: Dentistry Workers and Employers

- ASHRAE: Health Care Facilities

- BPE: Indoor Air Flow and COVID-19

- Bassett Mechanical: COVID-19 Educational Series- Part 1: Indoor Air Quality

- ScienceDirect: How can airborne transmission of COVID-19 indoors be minimised?

- ASHRAE: ASHRAE Position Document on Infectious Aerosols

- CDC: Interim Guidance for Businesses and Employers Responding to Coronavirus Disease 2019 (COVID-19), May 2020

- U.S. Department of Labor: Guidance on Preparing Workplaces for COVID-19

- Jamda: Practical Steps to Improve Air Flow in Long-Term Care Resident Rooms to Reduce COVID-19 Infection Risk

- CDC: COVID-19 Employer Information for Office Buildings

- AIHA: Reopening: Guidance for General Office Settings

- The American Institute for Architects: Re-occupancy Assessment Tool V1.0

.jpg)