Solutions

- Ambient Air Cleaners Learn More

Industries

Aerospace

Apparel & Clothing

Auto body repair

Chemicals and Plastics

Educational

Electronics

Farm & Heavy Equipment

Machine Shop

Metalworking

Misc. Operations

MRO

Municipal & DOT Garage

Museums & Artifacts

National Defense

Robotics

Vehicle Repair

Waste Management

Welding Shops

Processes

- 3D Printing

- Auto Shop

- Buffing and Polishing

- Cigarette and Tobacco Smoke

- Clothing Assembly Line

- Deburring

- Heavy Equipment Repair

- Indoor Pistol and Small Bore Rifle Range Ventilation

- Machine Shop

- Paleontology

- Pesticide Manufacturing

- Stainless Welding

- Steel Welding

- Textile Dyeing

- Torch Cutting Ventilation

- Waste Management Facilities

- Welding Shop

Engineering Control Methods

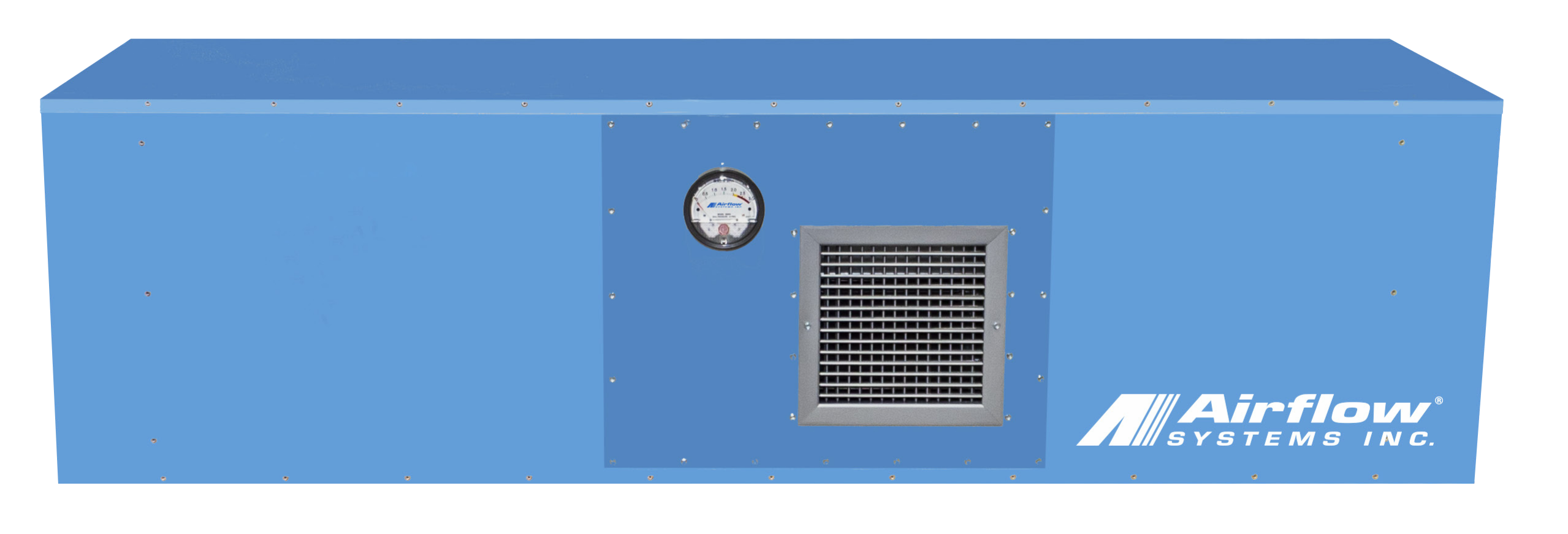

G-300 Series - Free hanging air cleaner - 4000 CFM

These systems operate as free-hanging media filter units, providing multi-stage filtration with up to four filter stages. Each model integrates high-efficiency fiberglass bag filters and pleated pre-filters for extended filter life and reduced maintenance cycles. The G-Series can be mounted on ceilings or walls, ensuring maximum flexibility while keeping valuable floor space free.

The design eliminates the need for ductwork and includes prewired connections to the junction box for fast installation. Standard operation is non-electrostatic, ensuring long-term reliability, and the modular construction allows scalable performance to meet facility-specific needs.

Optional enhancements are available to match varying demands. These include silencers for noise reduction, pressure gauge kits for filter monitoring, inlet plenums, spark baffle pre-filters, and overload disconnects. Units may also be ordered with galvanized or powder-coated steel finishes.

CONSTRUCTION

- Cabinet: 16 ga. steel, with galvanized or powder-coated finish

- Blower: Direct drive (9x9), improves reliability and efficiency up to 23% over belt drives

- Filters: High-efficiency media, 65% standard fiberglass bag filters (95% optional) with pleated pre-filters; disposable or cleanable

- Electrical: 0.75 HP – 120V; 3 HP – 208/230/460V; FLA 9.5–10.6A depending on model

- Dimensions:

G101 – 24" x 24" x 85" (225 lbs)

G301 – 24" x 24" x 85" (300 lbs)

G302-H2 – 24" x 48" x 85" (450 lbs)

G303-H3 – 24" x 72" x 85" (600 lbs)

G304 – 48" x 48" x 85" (750 lbs) - Noise Level: 75 dBA (standard), 79 dBA (3 HP)

KEY CRITERA

- Performance: Airflow capacities up to 4000 CFM, supporting tough industrial applications

- Energy Efficiency: Direct drive blower reduces energy use by up to 23% vs. belt-driven designs; optional smart controller reduces operating costs up to 70%

- Low Maintenance: Ultra-Seal® filter mounting prevents bypass, filters are tool-free, cleanable, and easily replaced

- Versatility: Wall- or ceiling-mounted, compact footprint, and modular cabinet design for scalable performance

- Noise Reduction: Optional silencer available to reduce operating sound levels

- Monitoring: Optional pressure gauge kit ensures optimal filter change intervals

SUITABLE FOR

- Wood Dust

- Ceramic Dust

- Grinding Dust

- Powders

- Welding Fumes

- Oil Smoke

- Shops and Schools

- Tool Rooms

IMPORTANT: For your Health and Safety, make sure to talk to an application engineer before purchasing.

- Stage 1 - Prefilter

- F70R T-3000, T-3500, T-4500 T-6000, T-7500, & T-140 units (24" x 24" x 22")

- 200, 202, 203, PAC91, Fan Pack 2 & F-120/122/240/360/480