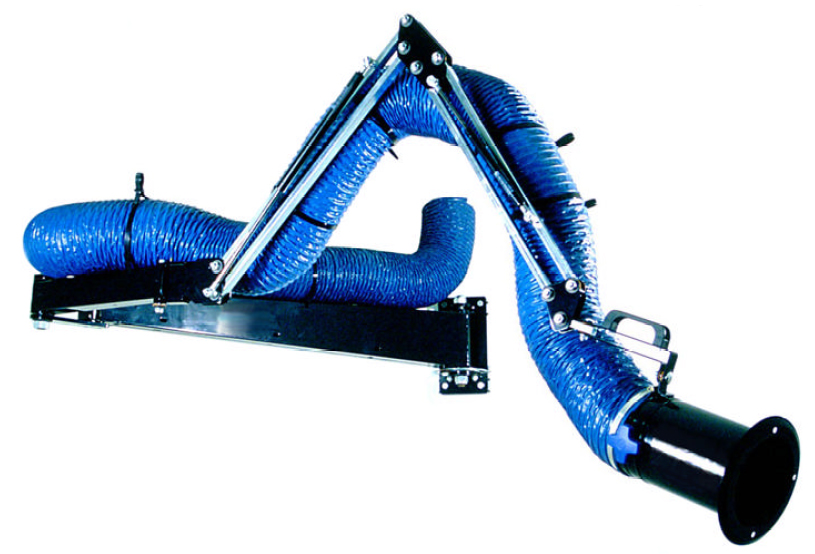

Extraction Arms

An extraction arm is a capture or receiving device designed to capture aerosols at the emission point before the contaminants have a chance to reach the workers' breathing space. Typically, it is the first and most crucial part of an LEV or Local Exhaust and Ventilation system. NB: Local exhaust ventilation can also be referred to as process ventilation or Industrial Ventilation, or Local Control ventilation.

Available in several different designs:

- Internally Supported

- Externally Supported

- Telescopic

- Mild or Stainless Steel Construction

- Lengths: Up to 45'

- 2.5" to 8" Ø Available

Typically the Extraction Arms are connected to a fixed extraction fan, Filter system or dust collector via direct mounting or a "Header Type" duct system.

For more info, relate to the links below:

Welding Productivity

Solidswiki

- Art's - Jewelry Manufacturing

- Art's - Lithography

- Art's - Screen Printing

- Art's - Stained Glass

- Auto body repair - Aluminum Welding

- Auto body repair - Buffing and Polishing

- Auto body repair - Steel Welding

- Auto body repair - Torch Cutting Ventilation

- Bio & Pharma - Pill Productions

- Bio & Pharma - Prosthetics & Orthotics

- Chemicals and Plastics - Pesticide Manufacturing

- Chemicals and Plastics - Plastic Manufacturing

- Chemicals and Plastics - Resin Manufacturing

- Chemicals and Plastics - Rubber Manufacturing

- Chemicals and Plastics - Soap Manufacturing

- Dental Offices - Operating Room

- Dental Offices - Procedure Room

- Educational - Auto Shop

- Educational - Chemistry Laboratories

- Educational - Machine Shop

- Educational - Welding Shop

- Electronics - Electronics Assembly Line

- Farm & Heavy Equipment - Farm Equipment Repair

- Farm & Heavy Equipment - Heavy Equipment Repair

- Food & Beverage - Animal Food Manufacturing

- Food & Beverage - Canning

- Food & Beverage - Food Packaging Plant

- Food & Beverage - Fruit Production

- Forensics - Forensic Laboratories

- Machine Shop - Core Grinding

- Machine Shop - Metal Polishing Belt

- Marine - Hull Building

- Mining & Quarrying - Drilling

- Misc. Operations - Mortuary Table

- Misc. Operations - Soldering

- MRO - Heavy Equipment Repair

- MRO - Steel Welding

- MRO - Torch Cutting Ventilation

- Municipal & DOT Garage - Vehicle Service and Maintenance

- Museums & Artifacts - Artifact Cleaning

- Museums & Artifacts - Paleontology

- National Defense - Military Vehicle Repair

- Public Transportation - Bus Maintenance and Repair

- Public Transportation - Subway Maintenance and Repair

- Refineries & Energy - Renewable Energy Manufacturing

- Vehicle Repair - Buffing and Polishing

- Vehicle Repair - Cars & Small Trucks Repair

- Vehicle Repair - Motorcycles & ATV Repair

- Welding Shops - Aluminum Welding

- Welding Shops - Copper Alloy Welding

- Welding Shops - Magnesium Welding

- Welding Shops - Nickel Welding

- Welding Shops - Stainless Welding

- Welding Shops - Steel Welding

- Welding Shops - Torch Cutting Ventilation

- Woodworking - Chainsaw

Yes, but only when systems are designed, installed, and used precisely. Unlike dilution ventilation, Extraction Arms can return significant energy savings and improvements in health and safety. However, the precision at which they must be designed, installed, and used can be complex. Lev-Co uses three procedures to determine the design and installation of our extraction arms. These three procedures are OSHA HOC (hierarchy of controls), MOC (management of change), and PSR (pre-start safety review) Lev-Co recommends that these three procedures, when appropriate, should be used when selecting extraction arms as a capture method.

Here are links to examples of these three procedures:

OSHA Hierarchy of Controls

MOC Management of Change Sample Document

PSR Pre-start Health and Safety Review

Extraction Arms are essential for maintaining a safe and healthy workplace. In many benchtop applications, such as welding and soldering, where a closed-off isolation chamber is not possible, a point source capture system is needed to keep the constant stream of smoke under control.

Depending on the rate and intensity of production in your facility, the rate of fumes and smoke may rapidly increase workers' risk as a result of the volume of smoke, heat, and consistency of fumes. While some processes require minimal extraction rates, others will need high-intensity extraction capabilities. We ensure that our wide range of configurations will accommodate your specific application.

Below is a full list of processes associated with extraction arms:

- Welding, Welding Fumes, and Soldering

- Laboratories and Laboratory Fumes

- Metalworking Fumes

- Grinding

- Cutting

- Oil Mist

- Painting

- Polishing

- Packaging

- Light Dust

For more insight on configurations for welding and metal-shop, read the article below:

Welding Productivity

You can also refer to our Industry Solution Page for a list of processes.

You can find a full selection by viewing our catalog.

The configuration of an extraction system depends on many variables. The intensity of your productions process determines the rate of the accumulation of fumes, which determines the rate of airflow needed to effectively capture, which then determines the required air : cloth ratio of your filter.

How do you determine a suitable configuration?

- What contaminant are you extracting?

- What is the rate of containment accumulation per second?

- What are the physical limitations/protocols of your facility?

- How often will it be used?

Things to consider:

- Capacity: How much flow will the extraction arm handle?

- Capture Velocity: Can the extraction accommodate the required capture velocity to capture the aerosol?

- Easy to Use: How many articulations/joints does the extraction arm have?

- Stay in Place: Does the extraction stay in place, how often do the joints need to be tightened?

- Extension Hoods: Do you need a large diameter extension hood?

- e.g. 36"Ø? (Optional)

- How large is your facility? How much reach do you need?

- How many workers are working with contaminants at any given time?

- Where are fumes being extracted? Pre-defined locations, or movable workstations?

- Can the extraction arm withstand the pressure/abrasion/corrosion/etc.?

For more questions about configurations and criteria, contact us, or click the link below to get a better understanding of the importance of accurate configurations.

Welding Productivity

Pro's:

- Remove airborne toxins at source before they enter any worker's breathing zone

- Low energy costs (heat loss, electrical energy)

- Allow the use of smaller filtration equipment

- Well suited for "on-demand" controls allowing for greater flow at the source, yet lower overall flow

- Some extraction arms allow the supporting of items like wire feeders, Compressed air cord reels, and electrical cord reels for increased productivity

- Better visibility through the addition of hood-mounted lighting solutions

- Optimized hoods, large-diameter receiving hoods, and hose extensions are effective solutions where capture or hood placement is difficult

- Hood can be rotated 90° (perpendicular to the floor), eliminating shadowing

- When used correctly, the operator can visually see the contaminant being safely drawn away from the process

- Options of 115 volt means the portable filter units are effortless to install anywhere in a facility

Con's:

- Operator needs to be comfortable with the use of the arm to ensure adequate capture

- Arms not always available in larger diameters for required capture velocity

- Production time lost to place the extraction arm in place

- Cannot always reach the point of emission

- Worker buy-in is not always achieved due to a lack of fume capture

- Fugitive emission released into the workspace

- Some extractors are not built to withstand the working environment

- Poor design can lead to excess capture velocity resulting in extra capture velocity (shielding gases loss) and air noise

Industrial workers are exposed to a variety of health hazards every day. As a result, these workers risk the possibility of becoming sick, ill, and in some cases, permanently disabled. According to a WHO estimate (WHO, 2000), unintentional poisonings led to 300,000 deaths in the year 2000.

It's our mission to diminish that figure, but it only works if the correct equipment is used, and configured correctly. Our team works to make the logistics of those questions as straightforward and coherent as possible, and as such, will work with you to provide you with the best extraction system that fits your worker's needs. This includes everything from accessibility and usability to longevity and reliability.

You can read more about the risks and preventions of fume extraction below:

OSHA

WHO

The integral flaw with dilution ventilation is the contaminants picked up by the system are not ultimately removed from the air. As a result, dilution ventilation is ineffective against most contaminants produced in industrial processes, such as metal fumes, abrasive dust, vapors, gases, and toxic chemicals. Local exhaust ventilation eliminates these issues through the capture of contaminants near or at the source of the contaminant, not allowing the contaminant to enter the breathing space, or the workplace atmosphere.

To read up more about the benefits of local exhaust ventilation versus dilution ventilation, refer to these links:

CCOHS

Use of Local Exhaust and Dilution Ventilation

The maintenance costs associated with our extraction arms are considerably low. Unlike some companies that construct extraction arms out of plastic and diecast white metal, all structural components of our products are made using mild/stainless steel, or aluminum.

Provided the system is adjusted correctly prior to use, and the hose is configured for your contaminant and application, these extraction arms will provide years of service with minimal maintenance.

Energy Saving:

With the use of a local exhaust ventilation system and capture at source functionality, the maintenance costs for your system will ultimately go down as a result of associated efficiency. With capture at source functionality, the area at which extraction is occurring is far smaller than the area a large duct vent would be pulling from, and as a result, far less energy is needed to complete the extraction, which runs components at lower stress levels, and boosts longevity, and reduces energy bills.

Do's:

- Use the extraction system for it's applicable contaminant

- Always refer to the manual before using the system for different contaminant

Don'ts:

- Don't use the extraction arm for incorrect applications.

- For example, if your extraction arm is configured for non-flammable contaminants, don't use it for contaminants such as VOCs

Our extraction arms come in a large range of configurations, including wall mounts, ceiling mounts, bench, and tabletop mounts. With a wide range of accessories, extraction arms can also be mounted to adjustable mounting configurations for wide span and reach.

You can find a list of Extraction Arm accessories here. For more questions about installation options, call our sales office.

_ME_Lab_%26_Bench_Top_-_Externally_Supported_-_2%27%273%27%274%27%27_%c3%98.jpg)